Thermally Conductive Molding Significantly Improves Battery Management Performance and Reliability

ALMOST 55% OF COMPONENT FAILURES ARE HEAT RELATED – THERMAL CYCLING CAUSES ELECTRONICS FAILURE

There is a significant need for high-performing thermally conductive solutions in the marketplace across a wide range of industries. As devices get smaller, faster, and more functional, the density of power used in smaller spaces can result in higher failure rates due to excess thermal energy. High-performing devices need effective thermal management solutions to prevent hot spots and device failures.

Thermal management in battery systems is becoming increasingly important as batteries become more prevalent in our daily lives.

From rechargeable power tools to delicate cell phone batteries, more efficient thermal conductivity and cooling management are essential for higher efficiency and fewer field failures. To ensure the best performance and safety of battery systems, thermal management techniques such as liquid cooling, conduction cooling, and active heat spreaders must be utilized.

THERMAL CYCLING IS ONE OF THE BIGGEST DRIVERS FOR DEVICE FAILURE

Thermal cycling of devices is one of the biggest drivers for electronic device failures. The physicochemical parameters that are responsible for a wide variety of failures in electronic components can be accelerated by heat.

As devices heat up due to high power demand or power surges, heat has to be moved out of the system before thermal fatigue occurs, leading to one of the biggest challenges in electronics, thermal management. For example, hot spots on printed circuit boards (PCBs) of battery management systems regularly impair the charging and discharging performance of systems. The battery management system may slow the charging process to reduce the heat stress on various components.

Temperature cycling is one of the main causes of electronic failure, and not designing devices with this risk in mind can result in unexpected product failure in the field. The current industry challenge is to design effective thermal management systems that can spread and radiate the heat away from the electronic components faster and more efficiently, driving improved performance and reliability.

Conformal coating and potting encapsulants are currently being utilized by the majority of devices in battery management systems to prevent failures from humidity, dust, and vibration, however, these types of materials are not designed for heat management and have poor thermal conductivity. Additionally, these materials typically require laborintensive masking processes without the benefit of improved thermal performance. As a result, the need for advanced thermal materials with superior heat transfer capabilities is essential to maintain the efficient and safe operation of these rechargeable battery systems.

HIGHLY FILLED POLYMERS CAN SIGNIFICANTLY REDUCE THERMAL FATIGUE BY ACTING AS A HEAT SPREADER

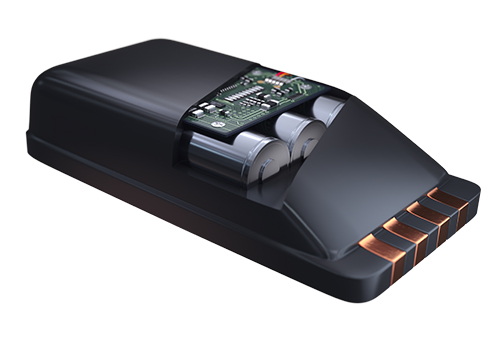

The Extrude to Fill (X2F) solution incorporates highly filled polymers into a patented controlled viscosity molding process (CVM), which solves four of the major reliability concerns in electronic devices (Dust, Humidity, Vibration, and Heat) by delivering a fully encapsulated device with the added performance of heat spreading thermal polymers.

To accomplish this, X2F utilizes patented pulse-pack technology along with viscosity control algorithms, sensors, and data collection to influence their lowpressure molding process. The X2F technology produces cutting edge high-performing thermally conductive parts for a variety of applications – eliminating hot spots via thermally conductive encapsulation.

By using what X2F calls controlled viscosity molding, the electronic components are not only more protected, but they will experience reduced temperature for added performance. Electronics and circuits are encapsulated by X2F utilizing a procedure that involves low pressure and controlled viscosity. This process does not damage sensitive components. With X2F, it is feasible to mold thermally conductive and highly filled materials with step-change improvements in material properties. Molding these types of materials with other technologies is nearly impossible.

THE BENEFITS OF THERMAL MOLDING ELECTRONICS

The benefits of thermal polymer molding process are simple: air is a poor conductor of heat. By utilizing thermally filled polymers in a CVM process, air is being replaced with thermal molding materials, acting as an effective heat spreader. This creates a thermal path to radiate heat away from temperature- sensitive devices.

This controlled viscosity molding provides the protection benefits of multiple technologies. It can be used as a potting, sealing, and conformal coating replacement for a manufacturer’s current generation of products. The X2F proprietary method makes it possible to build components that cannot be made using process-constrained or scale-restricted manufacturing techniques, such as injection molding or additive manufacturing. In addition, X2F often uses a process called skylining to encapsulate the unit with minimal material use, resulting in material cost savings and multiple design advantages.

ADDED PERFORMANCE & TEMPERATURE REDUCTION WITH X2F

X2F has validated 25 to 30% temperature reduction with thermally conductive polymers in battery management systems – resulting in faster charging, improved energy density, and a longer lifespan. Companies working with X2F have noted a significantly higher performance in battery management systems manufactured with their unique technology. This type of thermal management is critical for superior performance not only in battery management systems, but in motors, batteries, LED drivers, solar inverters, PCBs, and more.

RAPID PROTOTYPE DESIGN AND DEVELOPMENT

The X2F process can often include 3D printing to create these molds, which requires a much shorter lead time than traditional injection molding. With the X2F process, getting a product launched is significantly cheaper and quicker. Moreover, the X2F technology contributes to a more sustainable supply chain as a whole.

Their low-pressure, controlled viscosity technique not only results in high-performing parts, but also has a lower overall environmental impact from concept to completion. X2F parts routinely outperform those that are created using traditional processes, beginning with the raw materials that are used and continuing through the manufacturing and end-of-life cycles. In addition, manufacturing X2F products requires 50–90% less energy, providing groundbreaking advantages for green manufacturing.

Krayden, an engineered solutions distributor of adhesives, sealants, and specialty chemicals serving a wide array of global companies in the Aerospace, Transportation, Energy, Electronics, and General Industrial markets is currently partnering with X2F, providing global support and access to several material suppliers that design thermally filled polymers. thermally conductive polymer composite material (TC of 0.8 W/mK) reduced PCB temperature to 62oC compared to the PCB temperature with no thermal management solution (90oC).

In contrast, the PCB over-molded with the standard polymer, without fillers, worsened the PCB thermal performance, increasing PCB temperature to 93oC compared to the PCB with no thermal management solutions (90oC), effectively impeding thermal conductivity in the system.

Learn more about our unique low-pressure controlled viscosity molding technology, don’t hesitate to contact us.