X2F’s Controlled Viscosity Molding (CVM) Technology

Conventional injection molding relies on extreme heat and pressure to force material into a mold —conditions that can degrade polymer chains and cause defects like warpage and sink marks.

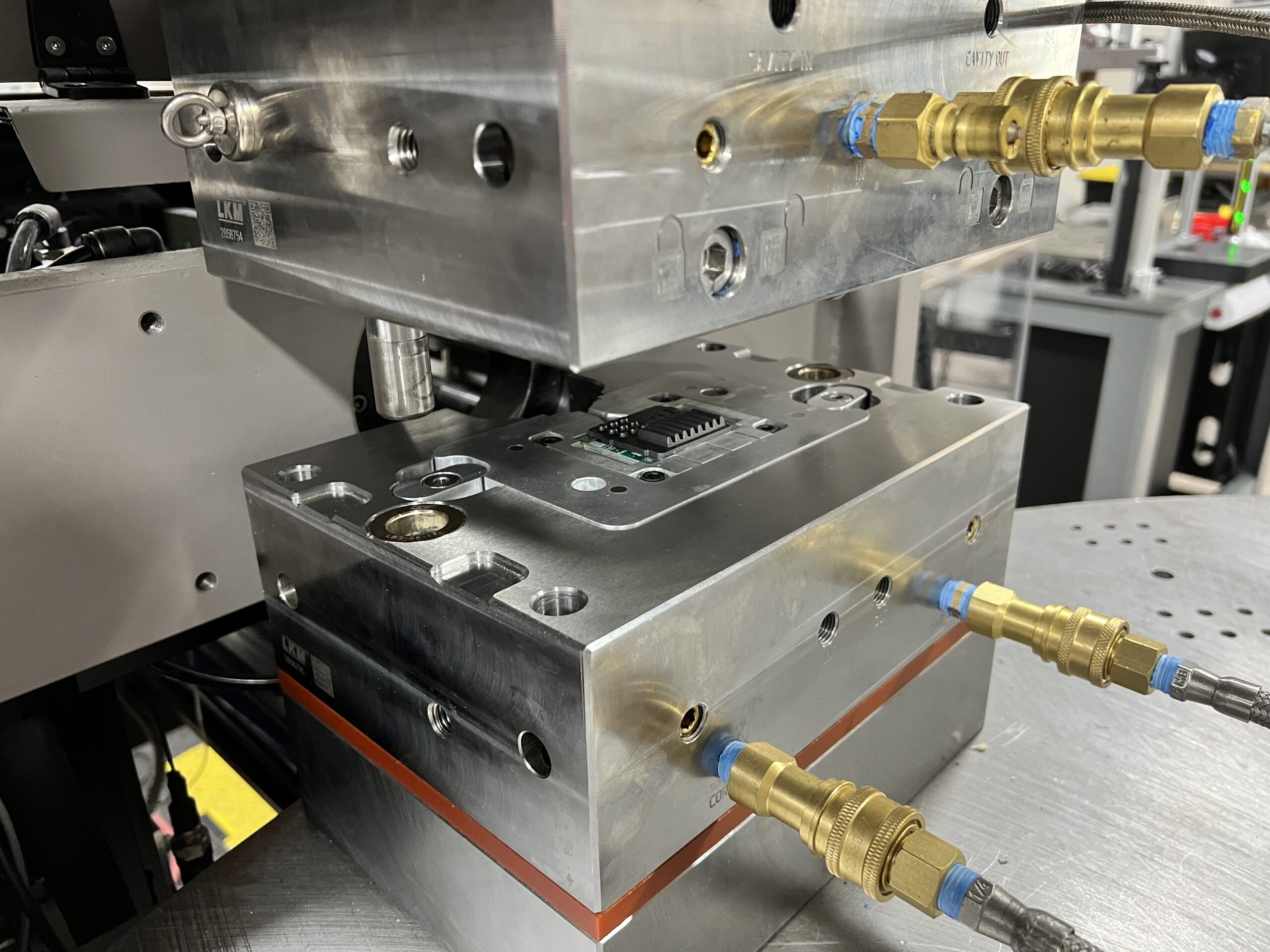

X2F’s CVM Systems offer a breakthrough alternative. Our patented low-pressure molding process continuously melts and pumps material into the mold while precisely controlling parameters like screw back pressure, cavity pressure, and torque. The result is optimized material flow, superior process stability, and consistently high-quality molded parts.

- X2F’s Patented Process: Eliminates the need for traditional injection molding’s screw, barrel, and heat-based shearing.

- Patented Extruder Screw: Enables on-demand polymer manipulation for precise control.

- Enhanced Flexibility: Adapts dynamically within the process, improving efficiency and customization.

- Preserves Material Integrity: Avoids damaging the molecular structure of polymers and prevents breakdown of glass fibers or additives.

- Dynamic Adaptability: Operates in real-time, unbound by conventional pre-measured “shot-to-shot” injection molding.

- X2F’s Process Is: Ideally suited for automated molding and seamless integration with automation.