X2F – The Future of Molding

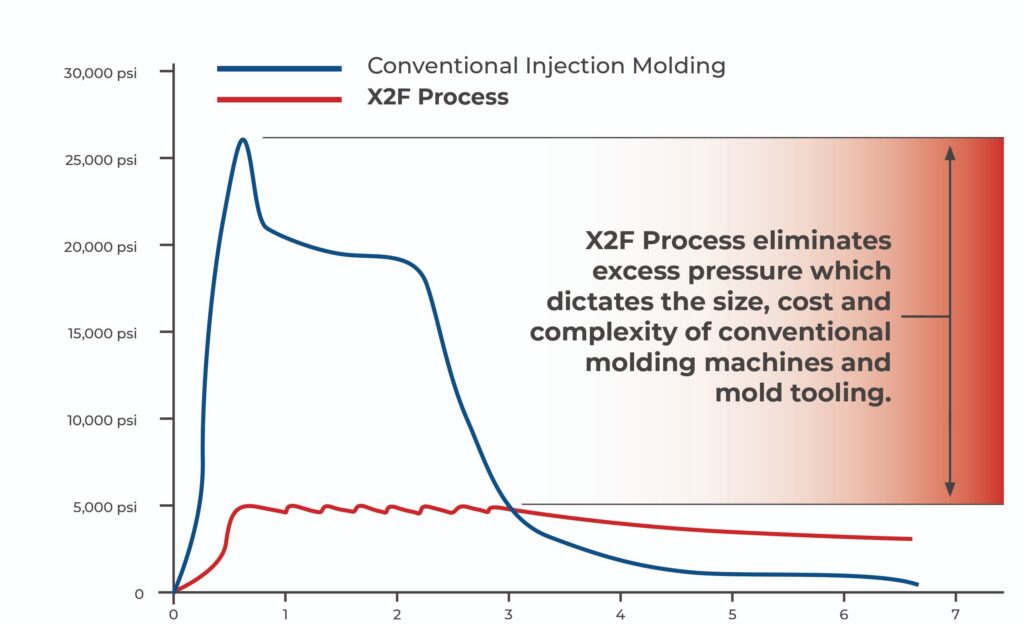

Our patented process accomplishes more with less—working with polymer chemistry, not against it– to mold complex materials and geometries without brute force, unlocking new design freedom and material possibilities.

X2F uses real-time control of flow velocity and viscosity to deliver cleaner surfaces, stronger parts, and consistent results—without relying on extreme pressure.

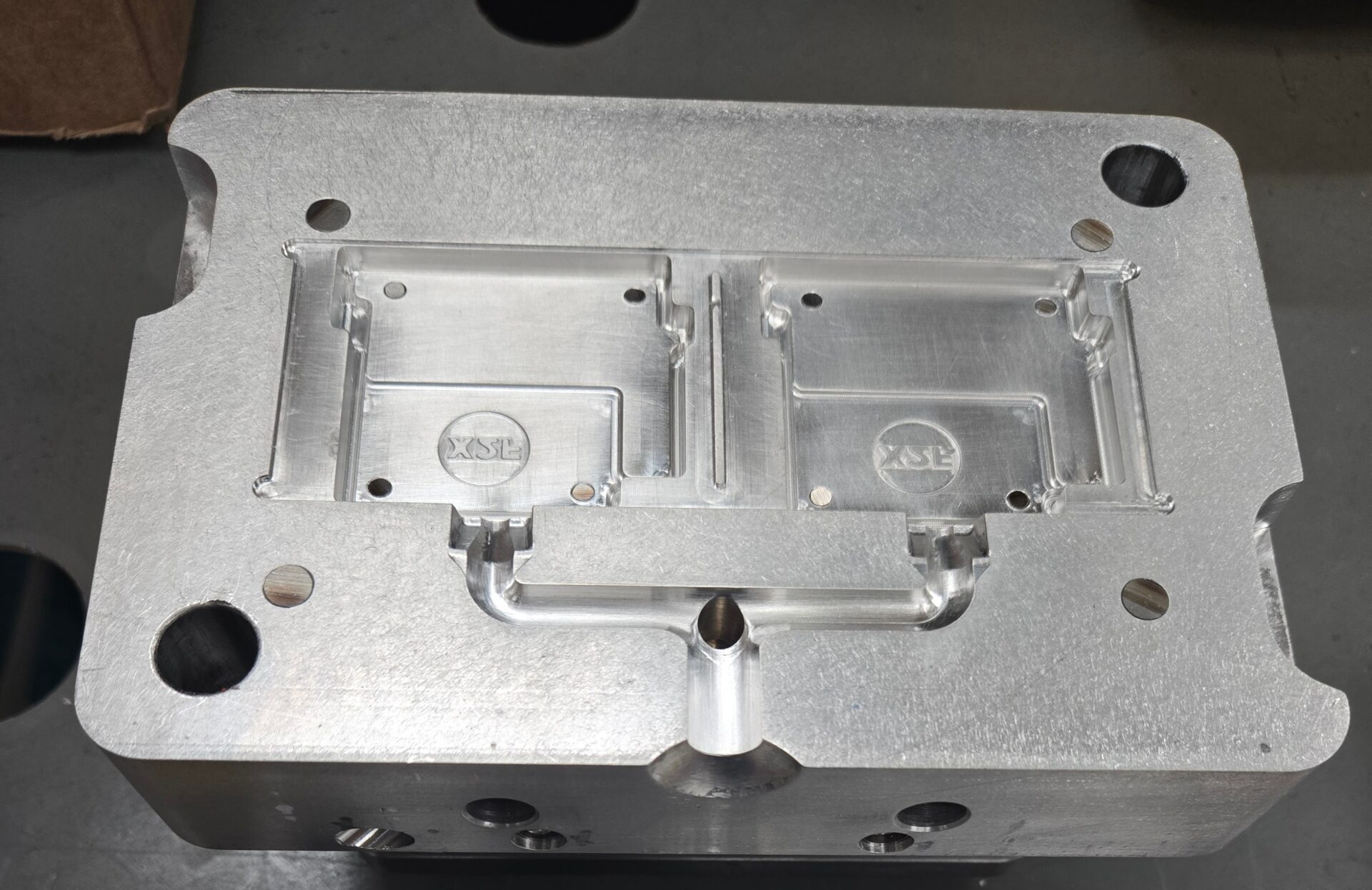

We mold advanced polymers, long-fiber compounds, and conductive materials that traditional injection processes can’t handle.