Our Story

Rick Fitzpatrick, a veteran of the injection molding industry, was very familiar with the limitations of conventional injection molding (CIM). Although CIM technology is one of the most versatile and commoditized manufacturing methods for producing plastic parts, it does not allow for the molding of polymers combined with fillers. Without this ability, engineers are limited as they look to develop next-generation molded products. Attempts to mold advanced engineering polymer composites with CIM processes and equipment lead to dramatically higher pressures, mold fill problems, residual molded-in stresses, decreased tool life, and low-quality parts. Unfortunately, adaptations to compensate for these problems are expensive and have inherent limited applications.

Rick was determined to find an easier and more economical solution. He started inventing Controlled Viscosity Molding (CVM) in his garage, developing the technology over a 15-year period. He machined all the components and developed the unique pressure control algorithms that resulted in 5 patents (now registered in 18 different countries) that became the backbone of X2F as it stands today.

Meanwhile, Rick’s friend from college, Ron Leach, was consulting for a private equity firm that was looking for an injection molding expert. That’s how Rick reconnected with Ron Leach, and together they founded X2F.

The X2F journey is a testament to the power of perseverance, teamwork and the spirit of innovation. Today, X2F uses these core values to guide the company in everything it does. X2F has built a dynamic team of experts dedicated to creating high-value advancements in multiple industries that have been limited by complex material processing challenges.

X2F Today

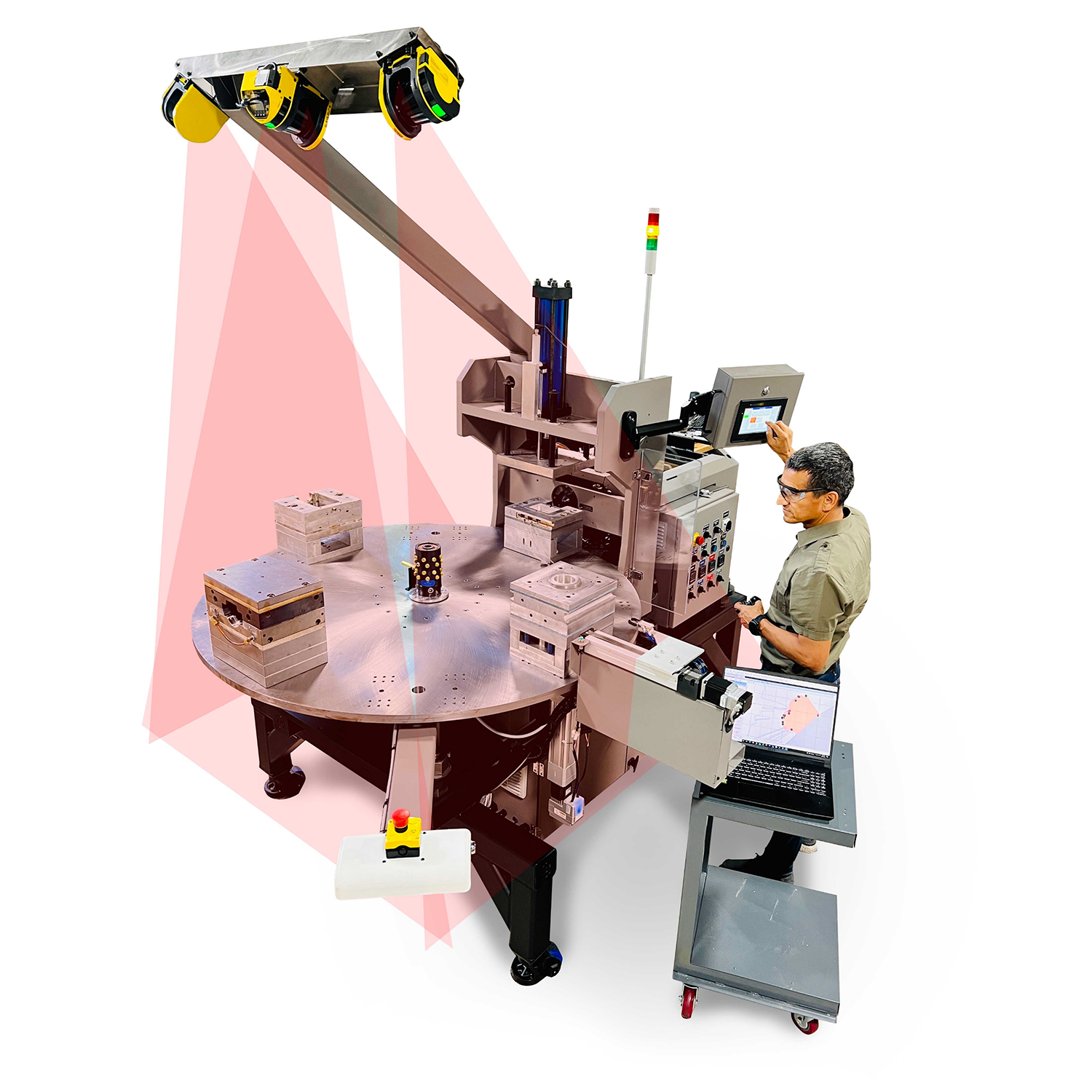

We are the exclusive provider of Controlled Viscosity Molding (CVM) technology and services. We offer complete CVM equipment solutions. Our facility is fully equipped for research and development, quick-turn prototyping, laboratory testing, and full-scale production. Our dedicated team of professionals work closely with customers to develop processes and capabilities to bring innovative solutions to their product.

Our goal is to support you with our technical expertise, to optimize your production and ensure our technology consistently yields high-quality parts that are molded with precisely the right properties and performance for your specific application.

X2F Success Stories

X2F technology with thermally conductive molding lowers temperature by 42.5°C for improved long-term reliability and performance.

All electronics generate heat, and over time, heat builds up creating the potential for heat related failures. The pursuit of practical solutions to complex thermal challenges has led to several innovations. For example, the development of ultra high-performance thermally conductive polymer composites. However, incorporating thermally conductive fillers, such as ceramic or metal particles, into polymers, causes the viscosity of the polymer material to change in ways that make them difficult to mold using conventional molding techniques, limiting the application of these advanced materials, until now.

Controlled Viscosity Molding technology developed by X2F is revolutionizing thermal management by enabling overmolding of electronics and batteries with highly filled thermally conductive polymer composites, providing a game changing, cost-effective and time-efficient thermal management solution that also protects sensitive components from environmental contamination and mechanical stresses such as shock and vibration. In a nutshell, X2F provides an innovative solution that significantly improves product quality, reliability and performance.

X2F technology produces in-molded heat-sink for automotive LED headlamps that is 49% lighter weight and 30% lower cost than cast aluminum alternatives.

In collaboration with one of the world’s leading manufacturers of high-quality polymer materials, X2F CVM equipment is producing thermally conductive automotive LED headlamps with in-molded thermally conductive polymer heat-sinks. This new product is a unique alternative to the cast aluminum heat-sinks typically used with LED headlamps and involves CVM molding by X2F to integrate sensitive LED electronics directly into the automotive headlamp housings – eliminating the weight and labor associated with the installation of aluminum heat-sinks, brackets, screws, thermal pastes and adhesives.

Moreover, X2F’s ability to mold thermally conductive materials has applications far beyond heat-sinks. Thermal management is critical for superior performance in batteries, motors, and printed circuit board applications. Depending on the specific application and materials used, utilizing X2F technology can achieve a final product that is 50% lighter weight, with a 30-200% improvement in performance and significant labor and cost savings.