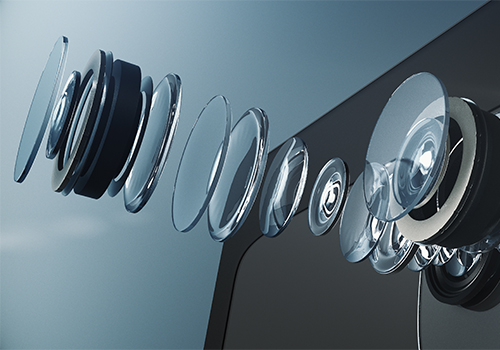

Innovating Beyond Conventional Molding with CVM

With X2F’s innovative controlled viscosity molding (CVM) technology, you can manufacture complex products using materials that were previously difficult to mold. Not only does this solve many of today’s urgent manufacturing problems, but it also enables innovation. With CVM technology, today’s product designers are reimagining what is possible. The possibilities are limitless!