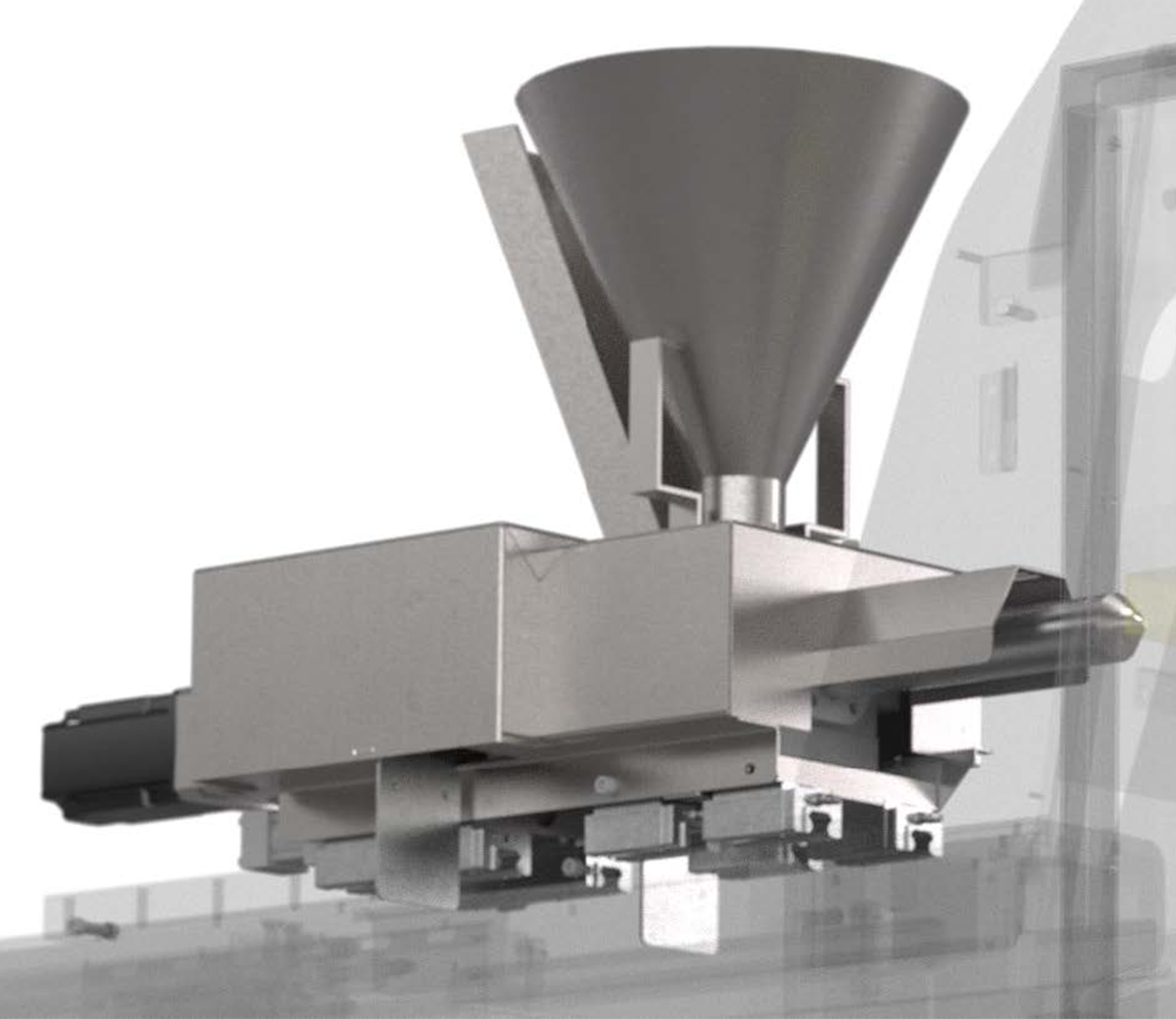

Melt Processing Unit

The E60Vi system utilizes a precision- controlled continuously rotating screw to extrude melt into the mold. This single-stage, pressure-controlled approach provides continuous feedback for adaptive process tuning throughout the filling and cooling cycles.

- No Check Ring, No Interruption.

Eliminating the check ring reduces system complexity, prevents backflow, lowers maintenance requirements, and ensures consistent flow. - Extrusion-Driven Filling

Melt is delivered directly into the mold cavity by the screw rotation — no plunger or secondary injection stage required. - Ultra-Flexible Shot Volumes

With extrusion-based filling, shot size is virtually unlimited, making it versatile across a wide range of part sizes. - Pulse Packing

Our patented pulse-packing technology ensures highly consistent packing with reduced shear stress — preserving polymer chain integrity and enhancing dimensional accuracy.

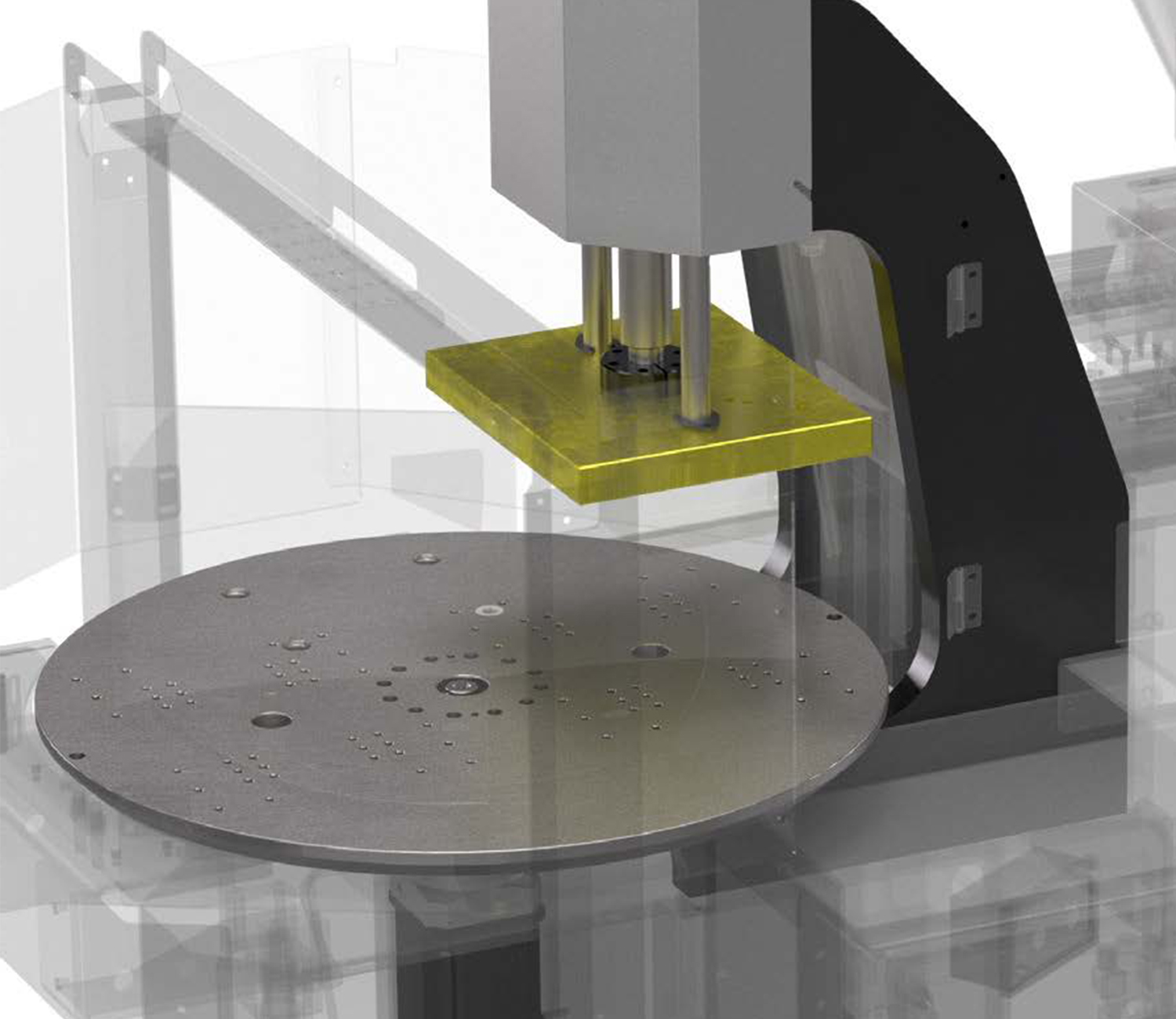

Clamp Unit

The E60Vi features a rugged servo-hydraulic clamping system housed in a compact C-frame structure. Engineered for full mold access and precision control, its tie-bar-free design creates a clean, unobstructed space — ideal for seamless integration with automation and mold-handling equipment.

- Tie-Bar-Free Architecture

Unrestricted access for tooling, automation, and part inspection — no limitations or obstructions. - Servo-Hydraulic Precision

Applies clamping force with speed and accuracy, supporting fast, repeatable open/close sequences. - Balanced , Centered Loading

The C-frame design ensures symmetric force distribution and precise mold alignment. - Lower Tonnage Requirements

Our low-pressure process reduces clamping force demands, improving energy efficiency and extending mold life.

Rotary Table

The E60Vi system features a high-speed, all-electric, servo-driven rotary indexing table engineered for high-performance and efficiency. Its two-station layout enables simultaneous molding and part handling for maximum productivity.

- All-Electric Direct Drive

A powerful, backlash-free servo motor delivers precise, repeatable movements. - +/- 180° Bidirectional Indexing

Fast, reversable rotation minimizes idle time and boosts overall throughput. - Seamless Integration

Directly built into the frame and perfectly aligned with the clamp for smooth synchronized operation. - Engineered for Productivity

Parallel mold actions allow mold 1 to close while mold 2 ejects and resets — ensuring continuous, high-efficiency cycling. - Built for Flexibility

Programmable indexing cycles accommodate complex mold layouts and evolving production demands.

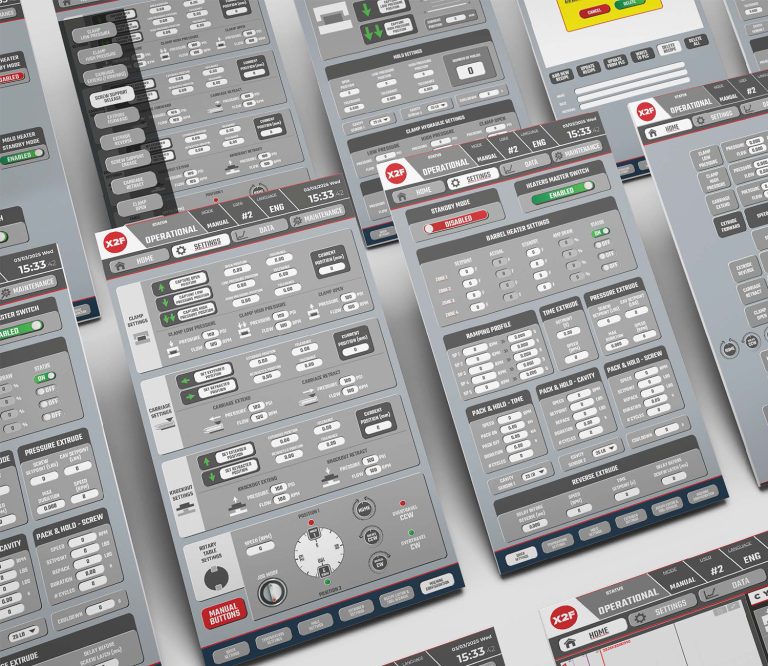

Human Machine Interface (HMI)

The E60Vi system features an intuitive, high-resolution Human Machine Interface (HMI) touchscreen, built on Siemens Programmable Logic Controller (PLC) architecture for industrial-grade reliability and future-ready flexibility.

- 15×6” Full HD Touchscreen

Intuitive navigation and crisp visuals make it easy to monitor and adjust machine parameters with precision. - 180° Swiveling Display

The pivoting HMI provides ergonomic access and optimal visibility from any working angle. - Modern, Gesture-Based Navigation

Familiar controls like swiping and zooming simplify operation and streamline setup. - Reliable Siemens PLC Architecture

Built on a proven control platform that’s customizable, scalable, and ready for advanced integration.